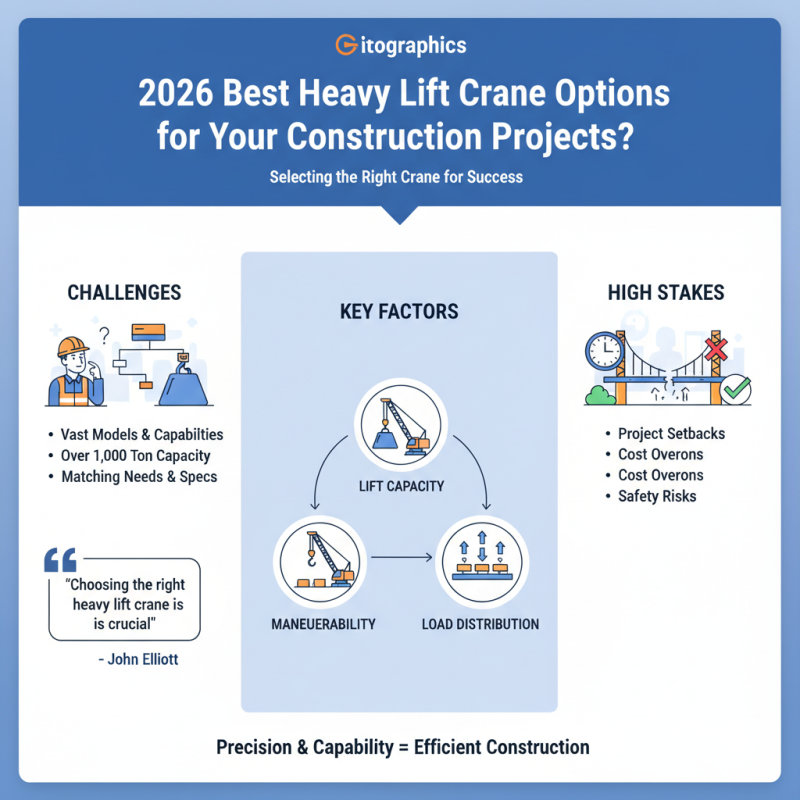

When selecting the best heavy lift crane for construction projects, decisions can be challenging. According to John Elliott, a renowned industry expert, “Choosing the right heavy lift crane is crucial for project success.” His insight emphasizes the importance of evaluating options carefully.

The world of heavy lift cranes is vast, featuring numerous models and capabilities. For example, some cranes can lift over 1,000 tons. This extraordinary capacity makes them essential for heavy construction and infrastructure work. However, with such diversity comes complexity. Companies often struggle to match their project needs with the right crane specifications.

Moreover, assessing crane options isn't just about capacity. Factors like maneuverability and load distribution play a vital role in performance. Projects can face setbacks if the wrong crane is chosen. The stakes are high. Precision and capability make all the difference when it comes to efficient construction.

Heavy lift cranes play a vital role in construction projects. Their ability to move heavy materials is unmatched. Construction sites often require lifting things that exceed regular crane capacities. Heavy lift cranes fill this gap effectively. They are essential for building skyscrapers, bridges, and large industrial structures.

Choosing the right crane can be challenging. It's crucial to assess the weight and size of the materials being lifted. Consider the crane’s reach and height capabilities. Sometimes, crews underestimate these requirements. Poor planning can lead to delays and increased costs. Pay careful attention to these details to avoid mishaps.

Tips: Always consult with experts when selecting a crane. Their experience can offer valuable insights. Schedule regular maintenance checks. This ensures optimal performance during critical lifts. Lastly, involve the crew in planning. Their hands-on experience can highlight potential issues early on. Engaging the entire team leads to improved safety and efficiency.

This chart illustrates the maximum lifting capacities of various heavy lift cranes that are essential for construction projects in 2026. Choosing the right crane type based on the lifting capacity is crucial for the efficiency and safety of construction operations.

When selecting a heavy lift crane for your construction needs, several key factors come into play. The load capacity is paramount. You need to assess what weight the crane must lift. Consider the heaviest items on your site. This ensures you choose a model that won't struggle with the demands of your project. Lastly, the crane's reach becomes crucial when dealing with tall structures or tight spaces.

Another factor is the operating environment. Indoor applications can benefit from smaller models, while outdoor settings may require larger, more robust cranes. Assess the terrain and any environmental challenges. Weather conditions can also impact crane operations, leading to downtime. Maintenance considerations are also essential. A reliable crane will require less frequent repairs and more uptime on-site.

Lastly, reflect on the crane's maneuverability. A crane that's easy to position and move can save time. It's important not to overlook crew training. Even the best crane won't perform effectively without skilled operators. Think about seeking training programs that can enhance safety and efficiency in crane operations.

When considering heavy lift cranes for construction projects in 2026, the selection process requires careful evaluation. Reports show that the demand for heavy lift cranes will grow by 5% annually. This growth is driven by infrastructure projects and industrial expansions. Factors such as load capacity, reach, and mobility are crucial. Many models are capable of lifting over 1,000 tons, which allows more versatility in challenging environments.

The recent market trends emphasize the importance of fuel efficiency and forerunner technology. Many operators are opting for cranes equipped with hybrid solutions. These cranes minimize carbon footprints while maintaining powerful lifting capabilities. However, the upfront costs of advanced models can be a barrier. Construction firms may hesitate to invest without guaranteed ROI.

Safety features are becoming a priority in crane selection. Operators now seek models with enhanced load monitoring systems and improved stability mechanisms. With increased automation and remote operation, risks can be mitigated. Yet, training remains essential. Many operators still feel unprepared to handle new tech. Finding a balance between innovation and operator readiness continues to be a challenge in the heavy lift crane sector.

| Model | Max Load Capacity (ton) | Boom Length (ft) | Operating Weight (ton) | Applications |

|---|---|---|---|---|

| Crane A | 500 | 200 | 150 | Industry & Infrastructure |

| Crane B | 400 | 180 | 130 | Maritime & Heavy Lifting |

| Crane C | 600 | 250 | 160 | Construction & Petrochemical |

| Crane D | 750 | 300 | 200 | Renewable Energy & Heavy Industrial |

When considering heavy lift cranes for construction projects, the decision to rent or buy is critical. The initial costs of purchasing heavy lift cranes can exceed $1 million, depending on the specifications. This can be daunting for smaller firms. However, ownership can lead to long-term savings, especially for companies that frequently require these cranes. According to industry reports, purchasing can yield a 15-20% return on investment over five years.

On the other hand, rental options provide flexibility. This approach can save capital in the short term. Renting allows companies to use state-of-the-art equipment without a hefty upfront price. Data shows that 57% of construction firms prefer renting for projects with fluctuating demands. However, rental fees can accumulate quickly. Companies may find themselves paying more in the long run if they consistently rent instead of purchasing.

The decision is not always clear-cut. Organizations must assess project duration, equipment usage frequency, and maintenance costs. Future growth plans also play a role. Both options have pros and cons that deserve careful consideration. Evaluating these factors helps determine the most economical and practical choice.

When utilizing heavy lift cranes, compliance with safety standards is crucial. Operators should always wear personal protective equipment. This includes hard hats, gloves, and steel-toed boots. Understanding the equipment's load capacity is fundamental. Overloading can lead to catastrophic failures, endangering lives and property.

Regular training sessions for crane operators are essential. These sessions should cover emergency procedures and equipment inspections. Operators must familiarize themselves with the specific crane they are using. Every model has unique features that require attention. Communication among crew members is vital during lifting operations. Hand signals or radios can prevent misunderstandings and ensure stability.

Despite strict guidelines, not all sites adhere to safety protocols. Sometimes, crews may rush to meet deadlines, ignoring crucial checks. Challenging weather conditions can also complicate operations. Operators must constantly assess their surroundings. Adjustments may be necessary to maintain safety. Reflecting on past incidents can guide improvements. Safety is not just a requirement but a commitment to protect everyone on the site.