When discussing heavy machinery, the term "national crane" often comes to mind. These cranes play a vital role in construction and logistics. They are designed to lift heavy loads, making them essential for various industries. Knowing the top models can help users make informed decisions.

Among the models, some stand out due to their reliability and performance. Each national crane has unique features that cater to specific needs. For some, size matters most. Others may prioritize lifting capacity. Understanding these distinctions is crucial for selecting the right equipment.

However, it's easy to overlook certain aspects. Not every model suits every project. Some cranes may offer speed but lack stability. Others may excel in lifting but struggle in tight spaces. Reflecting on these factors ensures a better match for your requirements. Whether you are a contractor or a project manager, knowing the best national cranes is invaluable. It leads to safe and efficient operations in challenging conditions.

National cranes play a vital role in various industries. Their innovative designs and capabilities set them apart in the market. Many models specialize in particular tasks, such as lifting heavy loads or navigating tight spaces. Some cranes are built for construction sites, while others excel in maintenance work. The versatility of these machines makes them indispensable.

Different models feature unique strengths. Some are highly mobile, allowing operators to reach difficult areas. Others focus on lifting capacity, handling massive weights with ease. However, not all models have the same reliability. Users occasionally report issues with stability. Regular maintenance is critical, yet some operators overlook this aspect. This can lead to safety concerns.

Understanding these models is essential for making informed decisions. Each crane has specific design elements that affect performance. For instance, boom length and load charts must be considered carefully. Exploring these nuances can sometimes feel overwhelming. Nonetheless, gaining this knowledge is worth the effort. Familiarity with various crane models enhances overall productivity and safety on the job.

When exploring the top national crane models, understanding their features is essential. Each model comes with specific capabilities. For example, some models have a maximum lifting capacity ranging from 10 to 150 tons. This variability allows for a broad range of applications, from construction to heavy-duty lifting.

Key specifications often highlight the boom length and operational radius. Some cranes boast a boom length exceeding 200 feet. This reach can significantly impact a project’s efficiency. Recent industry reports suggest that cranes with customizable features see a 30% increase in utilization. Operators appreciate flexibility, as it can adapt to various job site requirements.

While these models are advanced, challenges still exist. Maintenance often proves to be a hurdle. Downtime due to repairs can lead to inefficiencies. Industry experts recommend regular inspections to mitigate risks. Furthermore, operator training is frequently overlooked. Proper training ensures safety and maximizes performance. Investing in skilled operators can pay off in the long run, improving both productivity and safety metrics.

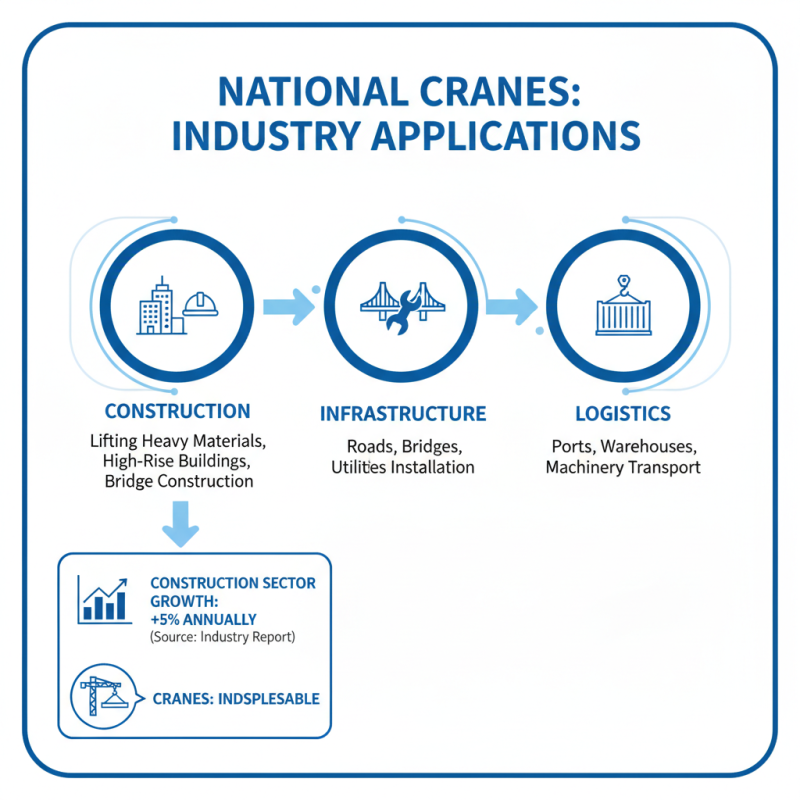

National cranes serve diverse applications across various industries. They play a critical role in construction, infrastructure, and logistics. A recent industry report noted that the construction sector is projected to grow by 5% annually. In this context, cranes are indispensable for tasks like lifting heavy materials and executing complex maneuvers. They are often used for bridge construction, high-rise buildings, and heavy machinery installations.

Moreover, national cranes find use in maintenance operations. They are essential in the energy sector, particularly for wind turbine installations. In fact, studies indicate that the global market for crane services in renewable energy is expected to reach $10 billion by 2025. However, it’s worth reflecting on the environmental impact of crane operations. While they support green initiatives, the operation of these machines can still generate significant emissions.

Safety is another crucial aspect. Despite advancements in technology, incidents during crane operations remain a concern. Reports suggest that nearly 20% of construction-related fatalities involve cranes. Regular training and adherence to safety protocols are vital but often overlooked. This gap highlights the need for continuous improvement in operational standards.

When comparing national crane models, several factors come into play. Each model has strengths and weaknesses. Consider lifting capacity, boom length, and maneuverability. Some cranes excel in tight spaces, while others perform well on large job sites.

Tips: Always check load charts. Knowing a crane’s limits is crucial. Miscalculating can lead to accidents and project delays.

The latest models have advanced features. However, they can be complex. Training operators is vital. Misunderstanding controls or features can cause inefficiencies. Budget constraints may influence model choice. Don't sacrifice safety for cost.

Some cranes might appear ideal at first glance. However, their real-world performance may disappoint. Users should seek feedback from current operators. Real-life experiences often reveal issues not detailed in brochures.

| Model | Maximum Lift Capacity (tons) | Boom Length (ft) | Overall Height (ft) | Weight (lbs) |

|---|---|---|---|---|

| Model A | 50 | 100 | 30 | 25,000 |

| Model B | 65 | 120 | 35 | 30,000 |

| Model C | 80 | 150 | 40 | 40,000 |

| Model D | 75 | 140 | 38 | 35,000 |

| Model E | 85 | 155 | 42 | 45,000 |

| Model F | 90 | 160 | 45 | 50,000 |

| Model G | 100 | 170 | 48 | 55,000 |

| Model H | 110 | 180 | 50 | 60,000 |

| Model I | 120 | 190 | 55 | 65,000 |

| Model J | 130 | 200 | 60 | 70,000 |

Future trends in national crane design focus on innovation and sustainability. Engineers aim to create cranes that are more efficient, flexible, and eco-friendly. Smart technology is becoming integral to crane operations. This includes sensors for safety and performance monitoring. Automation is also on the rise, allowing cranes to operate with minimal human input.

Tips: Consider adopting advanced software for crane management. It can optimize load distribution and reduce wear. Regular maintenance schedules should not be overlooked, as they ensure the longevity of equipment.

Another trend includes modular designs. These cranes can be adapted to various sites and tasks. This versatility can save time and costs. However, the challenge is ensuring stability and reliability during operation. Expect to see more emphasis on lightweight materials, enhancing portability without sacrificing strength.

Tips: Always evaluate the crane’s specs for your specific needs. A mismatch may lead to safety risks. Training operators on new technologies is crucial; they must be comfortable and proficient with advanced systems.